The most important thing to consider in an industrial environment, particularly around high-powered machinery like a Baccur shear. With its ability to cut and shear durable materials (like metal, composites etc.) it has the potential of being incredibly dangerous if used not with enough care. For the past several years, retrofitting a light curtain for retrofit baccur shear to a Baccur shear provides an attractive and effective alternative for improving safety without sacrificing machine production rates and operation.

In this blog we discuss light curtains, how they are used to retrofit a Baccur shear and the safety and performance advantages they provide. We will also look at a few other factors that should influence the selection, installation and maintenance of a light curtain for retrofit baccur shear for optimal safety effectiveness.

What is a light curtain?

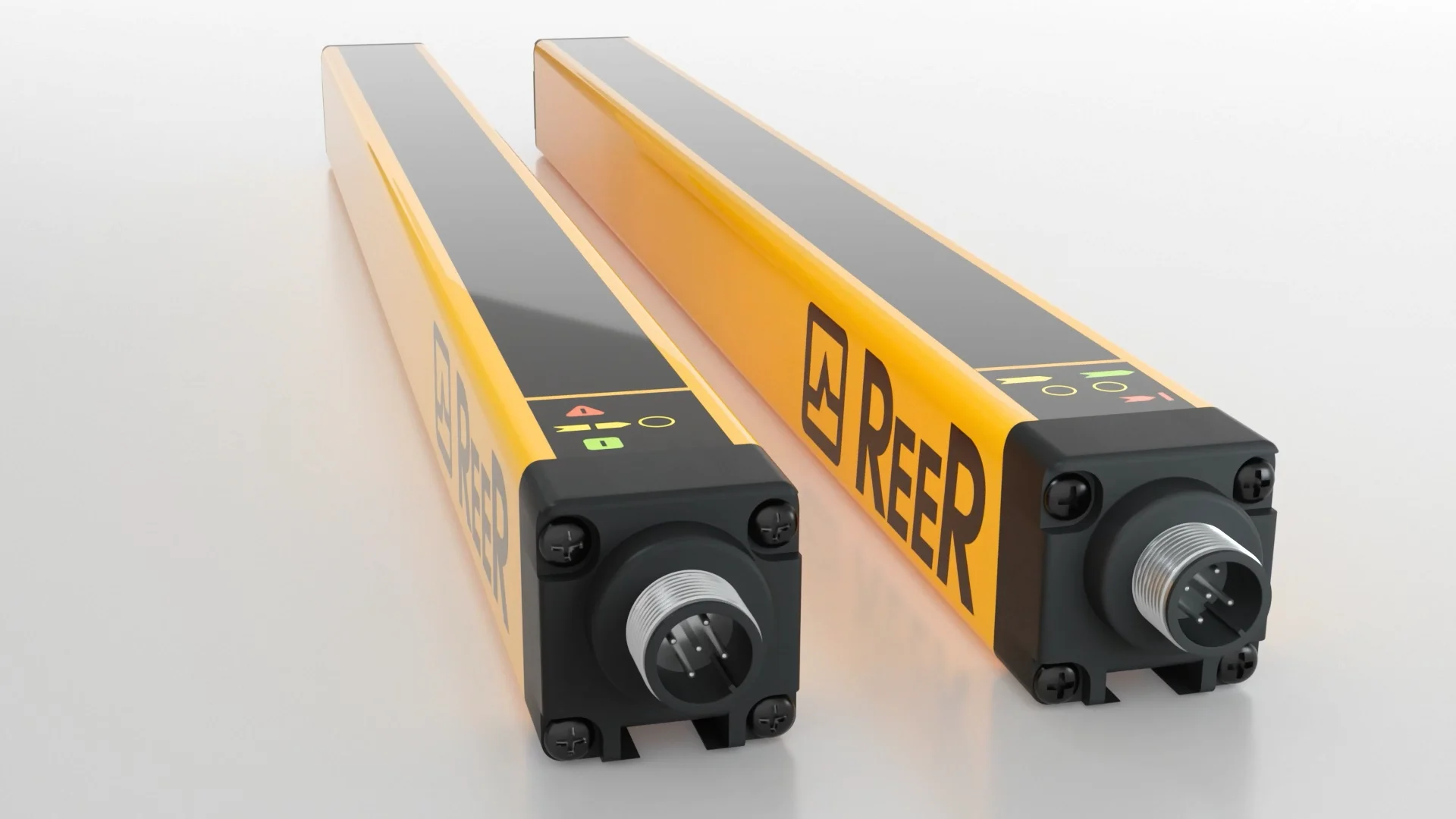

A light curtain is a safety instrument employed in industrial environments to establish an intangible wall of light rays throughout the operation region of equipment. A light curtain for retrofit baccur shear consists of two parts—an emitter and receiver—and it operates by projecting infrared beams between these two devices. If a beam gets interrupted by an object, hand or part of body the machine signal immediately to stop running and avoid injuries & accidents.

Light curtain for retrofit baccur shear typically find application in manufacturing and industrial environments with production equipment that workers interact with, such as press brakes, robotic arms, shearing machines. They serve as non-contact safety, which is a faster replacement for physical security that limits accessibility while stalling production.

Exploring the Importance of Baccur Shear

Various industries making bheavy work use a baccur shear, which is an engineering cutting machine. With its durable construction, it helps cut various steel, aluminum and other metals which find itself irreplaceably useful in fab shops, factories and construction industries.

But they are also risky to operate. The cutting each ingredient requires sharp blades and considerable force, which can lead to serious injury without adequate safeguards. Traditionally, safety came from physical barriers or operator training which have inherent limitations. A light curtain for retrofit baccur shear retrofit provides a time tested, dependable solution to improve safety while maintaining productivity.

Why Install a Light Curtain in Place of Classic Baccur Shear

Installing a light curtain for retrofit baccur shear on an older Baccur shear is just one example of upgrading safety features with modern technology. Shearing machines are usually designed many years prior, so many older models were developed without the benefits of advanced safety technology. Although they may be fine for cutting and longevity, it often lacks the safety mechanisms that you could break accidently in those modern industrial sectors.

Some good reasons a light curtain retrofit make sense:

Improved Operator Safety

To ensure that the machine operation stops immediately, if an object enters into machine danger zone, a light curtain is made use of. It minimizes the incidents of hand injuries or any other common serious accidents during feeding materials into machine and blade engagement.

Meeting Up To Modern Safety Regulations

In the US, OSHA (Occupational Safety and Health Administration) keep industrial safety standards in check through remote monitoring that contribute to safe work environment by enforcing using safeguarding devices on hazardous system. By retrofitting a light curtain for retrofit baccur shear, businesses can easily avoid such fines, penalties and liabilities in order to comply with these regulations.

Preserving Machine Longevity

Replacing the older Baccur shear with a light curtain for retrofit baccur shear provides an operational upgrade so you can continue to use that workhorse without compromising safety. This saves expensive replacements while updating the equipment to meet current safety expectations.

Understanding the Operation of a Light

In the case of a Baccur shear, this would involve positioning a light curtain for retrofit baccur shear around the machine’s cutting act. This safety feature operates within milliseconds, preventing the crash from happening altogether. For example, it can enable material to go through the light curtain without activating a stop but if a hand or finger passes through that it will be able to detect and shut off the machine.

Using a Baccur Shear Light Curtain

But, in this case, the advantage of not just basic safety that an integration of a light curtain for retrofit baccur shear offers. This helps to make it an attractive option for retrofitting old equipment such as the Baccur shear:

Non-Intrusive Safety Solution

This replaces the clunky physical guards, which can block views and access. It guarantees operators do not work in an environment with compromised safety.

Customizable Safety Features

Today’s light curtains are customizable, such as the adjustable detection ranges with varying beam gaps. This allows the system to be configured for the exact operating requirements of the Baccur shear.

Streamlined Business Operations

Light curtains do not need to be manually operated, unlike conventional safety measures. This helps avoid disruption, which in return facilitates the workflow and minimizes downtimes.

Cost-effective safety upgrade

A light curtain retrofit is typically less expensive than a machine replacement. It enables companies to get more life out of old equipment while increasing safety.

Assessment and Planning

Start by understanding the machine because you need to know how it is currently set up, and which danger zones must be protected. This involves analyzing the cutting zone, material feed points, and control mechanisms. After this evaluation the suitable light curtain model is determined.

Installation of components

Transmitter and receiver units (sensors) of the light curtain are mounted adjacent to either side of the danger zone. This positioning has to guarantee coverage of the entire hazardous area, with no gaps in-between the beams.

The process of integrating with control systems

The light curtain is directly interfaced with the Baccur shear’s control system so that if any beam gets interrupted, it can immediately send a stop signal to the shear. To do that might involve some changes to the machine, namely its wiring and control panel.

Configuration and Testing

After installation, the light curtain is set up based on what your machine will be performing. This involves defining detection ranges and beam sensitivity. Extensive tests are then carried out to ensure the system reacts correctly (and consistently).

Operator Training

Operators are trained in the operation of the light curtain and what do if the system is activated. This will allow them to use the machine correctly, without endangering themselves or anyone else.

Retrofitting Challenges and Considerations

A light curtain can hugely increase the safety of a Baccur shear, but retrofitting one to an existing machine comes with its own challenges. These challenges need to be resolved in order for effective implementation to happen:

Working Alongside Older Machines

Depending on the model, older Baccur shears may not feature some of the more sophisticated control system features necessary to integrate a light curtain smoothly. In those situations, you might have to change things around a bit or make upgrades.

Environmental Factors

Light curtains performance becomes inadequate when there are several factors like dust, vibration and temperature. To ensure reliability, proper maintenance and attention from environmental perspective is needed.

Initial Investment

Having an initial investment on equipment and installation makes retrofitting with a light curtain cost effective in the long run. Companies need to balance this expense against the safety and productivity gains and savings, however.

Long-Term Safety with a Light Curtain

Maintenance is required once it is installed so that the light curtain can perform properly. That means regular checks, cleaning of the emitter and receiver units, and checking the response system works. While it may deliver great results, the system must be calibrated from time to time to maintain high accuracy performance.

Operator and maintenance personnel training in operating and troubleshooting the light curtain will also contribute towards facilitating long life and reliability.

Conclusion

Genuine retrofitting of a Baccur shear with a light curtain is an easy way to improve safety and bring old machinery into line with modern standards. This state-of-the-art safety feature conserves both the operator and ancillary productivity, compliance, as well as machine life.

Gaining insight into how light curtains work, their advantages and drawbacks will help companies decide if it is time to upgrade their equipment. From either a manufacturer or an operator concerned about safety, the inclusion of a light curtain into your Baccur shear is considered to be an effective means of getting a safer and productive atmosphere in place.